High Process Versatility In Filtration Technology

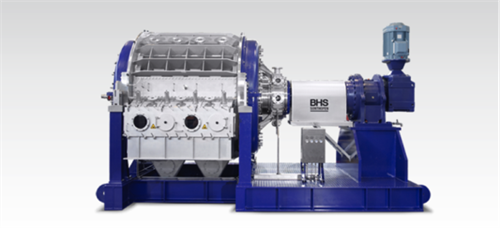

RPF X16 rotary pressure filter with TwinDrive

The BHS rotary pressure filter (type RPF) is a continuously operating filter for pressure filtration, allowing gas-tight cake treatment in several separate process steps. The cake can be discharged under atmospheric conditions.

The rotary pressure filter makes a large number of process steps possible during one drum revolution. After the suspension has been separated into filtrate and filter cake, further operations can be performed:

- Single- or multi-stage cake washing

- Displacement washing, counter-current washing or closed-cycle washing

- Reslurrying

- Solvent exchange

- Steaming, extraction

- Mechanical or thermal cake dewatering

All process steps are performed in separate segment zones inside the filter. This allows filtrates and other fluids to be drained off separately.

The rotary pressure filter is a completely self-contained unit allowing gas-tight integration into a production process. This enables the rotary pressure filter to be implemented even in operating environments subject to strict safety or hygiene regulations.

The rotary pressure filter operates at a pressure of up to 7 bar (g) and operating temperatures from approx. -20° to approx. 160° Celsius. In all process steps, pressure is generated hydraulically and not pneumatically by gas layers. This allows an individual process optimization of each operation step.

Each process step is sealed off as an independent segment zone inside the rotary pressure filter by means of pressure-tight separating elements. The cake can be discharged directly at atmospheric pressure.

The BHS rotary pressure filter is a further development of the solid filter described in the technical literature.

Representation Of The Individual Process Steps In The Rotary Pressure Filter

Phase 1: Suspension Feed and Filtration

Phase 2: Cake Washing

Phase 3: Cake Drying

Phase 4: Cake Discharge

Process Criteria

The BHS rotary pressure filter works on the principle of cake filtration and can fulfill the following process criteria.

|

Operating Method |

Continuous |

|

Operating Pressure |

Up to 7 bar (g) |

|

Operating Temperature |

Up to 160°C |

|

Solids Content (Suspension) |

Up to 60% (by weight) |

|

Cake Thickness |

Up to 175 mm |

|

Grain Size |

10 - 500 μm |

|

Filter Output - Suspension |

Up to 15 m³/m² h |

|

Filter Output - Dry Solids |

Up to 15,000 kg/m² h |

|

Active Filter Surface |

0.12 - 8.6 m² |