- Low Pressure Centrifugal Fans

Static pressure rise is below 300 mm.W.G. in this type of centrifugal fans.

- Applications:

- Maritime and terrestrial boilers

- Forced draft fans

- Induced draft fans

- Gas recirculation fans

- Industrial ventilation in general

- Fans for the mining industry

- Specifications:

- Large volume and pressure of up to 700 mm W.G.

- Special rotors with double back-bent blades

- 82% static efficiency

- Specially designed EHSL rotors with AIRFOIL stream lined blades that can reach 90% static efficiency.

- Medium Pressure Centrifugal Fans

Fans are considered medium pressure when static pressure is between 200 and 800 mm.W.G.

- Applications:

- Boiler for shipping and other industries

- Cement plants: Oven draft fan, Mill draft fan, clinker cooler draft fan, etc

- Cellulose factories: Draft fan for all kind of boilers

- Thermal power stations: Induced draft fans, forced draft fan, gas recirculation fan

- Sintering and pelletizing incinerators and scrubber exhaust

- Chemical and Petrochemical industries.

- Glass industry

- Gas transport

- Industrial depuration

- Waste incineration

- Specifications:

- Pressure of up to 1,200 mm W.G.

- Pressure of up to 2,500 mm W.G. in one stage by using special alloy steel.

- 88% static efficiency

- Different designed blade for different special applications.

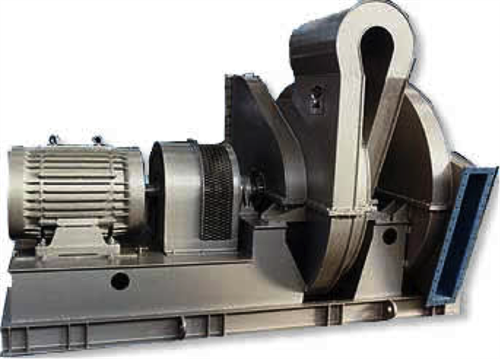

- High Pressure Centrifugal Fans, Blowers

These fans work with pressures of up to 3,000 mm.W.G

- Applications:

- Boilers for shipping and other industries

- Scrubber exhaust

- Pneumatic conveyors

- Sinterizing of minerals

- Burners

- Gas transport

- Venturi system depuration plants

- Primary air in thermal power stations

- Water purifying plants

- Specifications:

- Pressure of up to 2,500 mm W.G. at one step.

- Pressure of up to 7,000 mm W.G. with several compression steps.

- Efficiency up to 85%

- Centrifugal Fans for Special Applications

- ENERGETIC GAS FANS

- Great solidity

- Gas tight models

- Anti-spark models

- CORROSIVE GAS FANS

- In all kind of stainless steel

- Ebonite rotor and volute

- Cast volutes

- HOT GAS FANS

- Up to 900 °C

- Support in shaft area

- Refractory steels

- Oil lubricated and water cooled bearings

- ·FANS FOR GAS WITH SUSPENDED ABRASIVE DUST

- Radial or flat backward inclined blades

- Abrasion resistant steels and linings in maximum erosion zones

- FANS OF GREAT PERIPHERAL SPEED

- For pressures up to 3000 mm.W.G. at one compression step

- In special high resistance alloy steels

- FANS AT VARIOUS COMPRESSION STEPS

- Providing for pressures up to 8.000 mm.W.G